NLT-Concrete Composite Floor Test Completed

Nail-Laminated Timber (NLT) is a structural product, typically made of dimension lumber laminations that are stacked on edge and fastened with nails. It is widely used as deck and diaphragm elements for bridges and buildings. Canada Wood China (CW China) has been working to promote NTL applications in buildings in China through a program that entails developing market access solutions, engaging on codes and standards, organization education sessions and bringing in expert support for project designs.

The Tianjin Haibo Bay hotel demonstration project was designed to use an NLT-concrete slab composite floor system. However, there’s currently no Chinese product/manufacturing standard for NLT and the in-plane load transfer across lamination joints is not well understood by local authorities. Thus, a performance test by the Chinese Over-limit Design Review Committee was required. This testing included 3 self-tapping screw tensile tests, 30 push-out tests and 3 diaphragm stability tests.

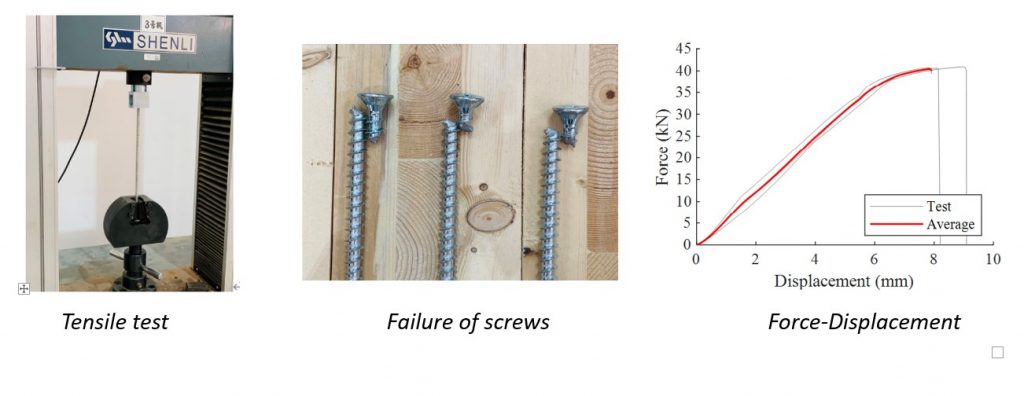

1. Self-tapping screw tensile test – Determine the tensile/yield strength of self-tapping screws

As a material component required for NLT slabs, the tensile test of three self-tapping screw samples was carried out. The average tensile strength of the screws was measured at 40.74kN.

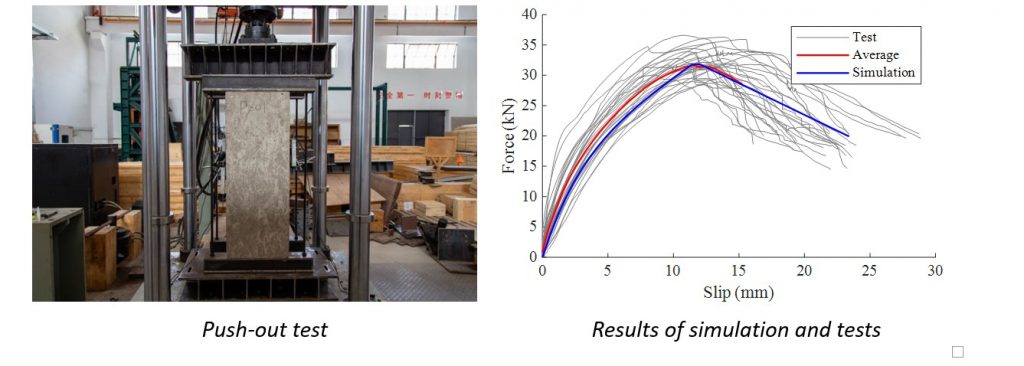

2. Push-out test – Determine the slip modulus of one screw

30 push-out specimens were fabricated and tested. The results indicate that the failure of specimens was mainly caused by the cracking of the concrete and the yielding of the self-tapping screws. The statistical analysis of 30 specimens shows that the average initial slip modulus of the shear connection is 6.92kN/mm with a coefficient of variation of 13.66%. The average value of shear capacity is 32.4kN with a coefficient of variation of 6.54%. These results indicate that this type of self-tapping screw performs well as a shear connector.

Based on the numerical analysis program ABAQUS, a finite element model was established using the improved Stewart hysteresis model to further investigate the behaviour of the specimens.

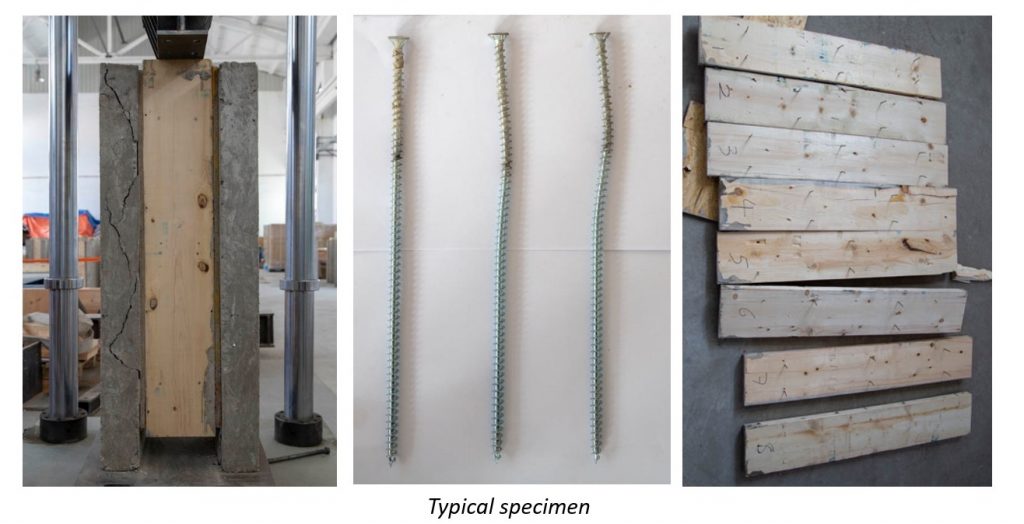

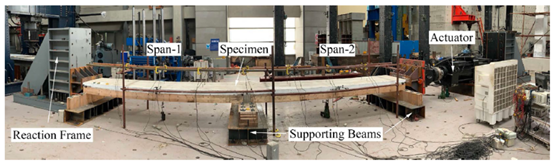

3. NLT-concrete composite floor stability test – Verify the degrees of composite action in the 2 directions (+Z and -Z way) and ultimate load bearing capacity of the connection between NLT-concrete composite floor and RC core

The NLT and the screw shearing connections provided strong out-of-plane support, ensuring concrete crushing at the loading edge happens before the buckling failure. The seismic design expert panel review opinions related to the integrity of the connections in NLT-concrete composite floors are therefore verified. The deformation conforms to the 1st buckling mode of 2-span floors. The failure mode is the material failure of concrete, with no evident damage occurring to the shearing connections. The average compression capacity was measured at 26.5MPa, which is larger than the design value 15.0MPa.

The above tests were conducted at the Tongji University Civil Engineering Lab starting from November 2020 and were completed on July 12, 2022. The results were better than expected, and this should help lead to greater acceptance of NLT applications in mass timber buildings as well as an advancement in China’s wood structure codes and standards.

The Haibo Bay hotel project has been nominated and accepted as a 13th Five Year national technology innovation project. The implementation of this demonstration project solves some of the key technical challenges of wood hybrid structure system research and engineering demonstration. This demonstrates the technical innovation with the integrated hybrid material applications that underwent scientific verification and testing. The results will be helpful to promote the technical achievements of wood structures, and a video summary report was produced with the professional assistance of Tongji University to explain everything.

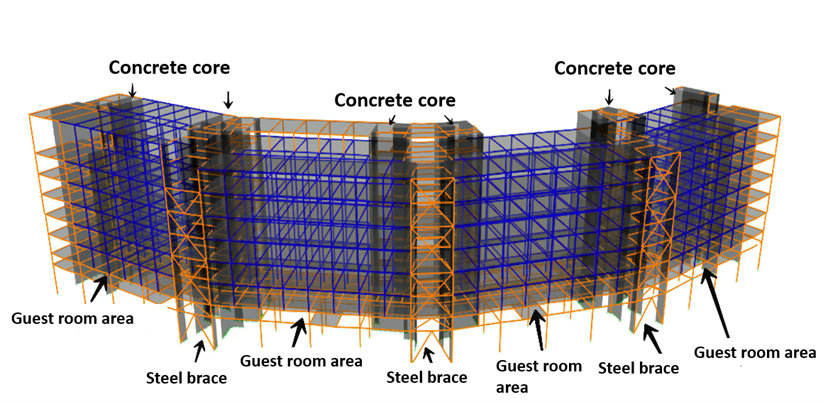

Haibo Bay Hotel Project information

The Haibo Bay Hotel project is a design for a potential project to be located in the Binhai New Area in the city of Tianjin. It is designed to be a hybrid seven-storey building supported by concrete pods and glue-laminated timber (GLT) with NLT floor slabs. The current code only permits glulam construction up to five stories, so this seven-floor hotel which includes six levels of GLT structural columns is expected to be a demonstration case that can help push the codes forward. While the project has been postponed due to the impact of COVID-19 on the travel and hotel industry, the design work and the associated NLT testing programs remain as a strong case for the possibilities for mass timber projects in China.