Prefabrication: A trend that’s here to stay

Using timber, mineral, and metal together is nothing new in construction, but prefabricating them together is a modern and cost-effective addition to the industry.

The development of the prefabrication industry is a priority of the Chinese government. Policies in 2020 required that construction projects have 15% of components prefabricated, with the requirements expected to increase to 30% by 2025. Shanghai is leading on these new standards, setting off-site prefabrication rates to 50%.

Why Infill Wall

One way of combining these components together before construction is the wood infill wall system that can be used in external (non-load bearing) or internal applications. Wood infill wall is manufactured from dimensional lumber and drywall, then installed between concrete floors, ceilings and pillars. The walls are both energy efficient and well-suited for prefabrication, which aligns with Chinese and Korean policy initiatives emphasizing this new construction method.

The system has code approval for residential and office buildings up to 6 floors for exterior non-load bearing uses, and up to 18 floors for interior infill uses on hybrid buildings.

As building becomes intentionally more industrialized in China, the industry is being redefined to create a new era for construction. The industrialization of construction increases labour productivity by delegating labour-intensive processes to machines. This leaner construction is both cost-effective and mitigates environmental pollution.

Our Approach

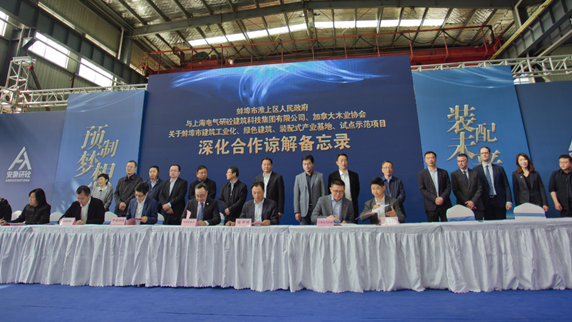

In line with this target, Canada Wood China collaborated with one of the largest precast concrete manufacturers Matechstone to accelerate the development of wood infill wall systems for China’s construction industries. Build on Canada Wood China’s years of technical research and market development strategies, the infill wall system has now been successfully used in several demonstration and commercial projects.

Our marketing and technical programs focus on building the awareness and develop technical solutions to address issues around structural connection, sound and fire safety.

We engage with targeted, large size companies to develop a product with a clear go-to-market strategy that can enable commercial demonstration projects and position wood building systems as scalable technologies for the prefabrication market

Achievements

Our collaboration with Matechstone progressed from a test project in Changzhou to the Taixing R & D center installation employing Prefabricated Energy-saving Cladding (PEC) system 1.0, to the development of a wall with higher prefabrication rates and redesigned connections marketed as PEC system 2.0 and applied in the Rugao Intelligent Manufacturing Center. MTS patented the PEC system in 2020. The PEC infill wall systems have been successfully commercialized in key markets, with many opportunities for applications in non-residential and industrial building segments.

The infill wall showcases how Canadian wood construction technologies can be transferred to China’s hybrid construction industry, opening new opportunities for Canadian wood in the mainstream building sector.