Featured: The Wood Newspaper Interview with Korea Forest Service

Recently, Korea’s Ministry of Land, Infrastructure and Transport relaxed the codes limiting the use of wood in buildings. The restrictions of 18m for roof height, 15m for eave height, and a cap on floor area of 3000m2 and under were removed from the national standards for wood construction. It is believed this code change will stimulate the expansion of large-scale wood buildings, furthering South Korea’s ambitions toward more sustainable building practices. The Namu Shinmun (The Wood Newspaper) interviewed Lim Young-Seok, Director of the Korea Forest Service (KFS)’s Timber Industry Division, to explore the implication of this code change and discuss the organization’s plans for the future.

Please elaborate on how abolishing the height limit for wooden buildings could impact the industry.

The abolition of the height limit for wooden buildings means that Korea can now participate in the era of high-rise wooden buildings, as seen in recent overseas cases.

Wooden buildings offer aesthetic and comfortable living to people through scenic beauty, insulation and humidity control, and deliver carbon sequestration benefits as a response to the climate crisis. However, code restrictions on wood buildings’ scale and height have limited the choices, and industry growth, for a long time.

Although various limitations and prejudices exist toward timber use in heavy timber and light wood frame construction, the advancement of innovative engineered wood products like Cross-Laminated Timber has proven these materials can be used in the construction of taller buildings.

The codes and standards improvement doesn’t mean Korea can now start building 80m or higher with wood immediately. Although Korea has recognized the performance of engineered wood products, there is much work still to be done in order to solve technical issues like fire resistance and noise control between party floors. I hope the landscape of our cities will change after those concerns are all addressed.

If high-rise wooden construction initiatives can thrive in the future, our timber industry will be able to make a huge contribution to the realization of a carbon-neutral society.

KFC has implemented key programs such as The Korea Wood Design Awards, The Timber Building Service Advisory Group and The Awards for Excellent Public Sector Wooden Construction. Could you please comment on the impact of those programs, and explain how the advisory group mechanism works?

In Korea’s construction field, timber is still perceived as a pricey construction material, and the wood building industry is not as developed as its competitors. For these reasons, it’s not so easy for owners to decide on wooden construction.

To raise awareness for quality-built wood buildings, we are promoting the Korea Wood Design Awards – together with the Korea Wood Construction Association – which this year marked its 18th anniversary.

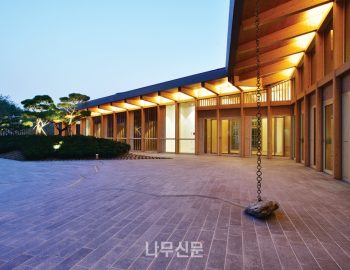

Looking at the entries for 2020, it’s clear that wooden structures are expanding into various sectors from public institutions such as the Swiss Embassy and the Dangjin City Council Library, to general housing projects. The advancement of wood-building technologies has led to some beautiful engineering design, as seen in the award entries. The winning projects have also caught attention from media and influencers.

We think the best way to promote wood in architecture is to encourage more wood use in public building segments. So in April 2020, we launched a task force to consult on the design, construction, and maintenance of government-funded public buildings made of wood.

The members of this timber building service advisory group, which consists of 46 experts, are elected from government agencies and organizations. The group has provided support to more than 10 projects in 2020, and their first consultation fees were funded by KFS.

At the same time, from 2019, through the Awards for Excellent Public Sector Wooden Buildings initiative, we continue to raise the awareness of wood construction among government procurement agencies. Recently we have observed growing interest in, and participation of, local governments in using wood to construct public buildings.

Please let us know if there are other policies and projects related to wooden construction that the Korea Forest Service is implementing.

Korea has a stable wooden house market, with average housing starts of exceeding 10,000 annually. We have developed eight standard wooden house designs. They can be downloaded for free from the homepages of the Korea Forest Service, the National Institute of Forest Science and the Center for Return to Farming.

We intend to improve housing performance and promote domestic timber use by developing high-quality, affordable wooden houses for those who are returning to rural areas. If a returnee uses more than 30% of domestic timber when constructing a new wooden house, the homeowners are eligible for a loan of up to KRW 100 million from the Forest Business Comprehensive Fund.

In addition to this, we plan to develop technical manuals for the design, construction, inspection and maintenance of public buildings built with wood.

KFS carries out a wide range of research projects to study the performance of wood building in the areas of fireproofing, sound control and thermal insulation. We are also conducting research on ways to promote the use of domestic wood.

KFS plans to formulate a nationwide timber city roadmap with the goal of expanding the markets for wood construction in multiple applications.

There are voices saying some prerequisites must be resolved before these relaxed measures can lead to an expanded and growing wood building industry. Most importantly: fire-resistant construction certification, sound insulation, and party-floor noise control. Please tell us about the current progress and future plans within the Korea Forest Service to solve this problem.

Korean building laws mandate the use of fire-resistant materials in major structural elements of buildings. In order to receive a fire-resistant construction certification, you must undergo accredited fire resistance performance tests.

In other words, the current regulations are not only expensive but also time-consuming — it takes more than a year to wait for the tests, and it requires a certification extension every five years. So far only six companies have achieved the 1-hour fire-resistant certificate for Glue-Laminated Timber, which is a key building material in large-scale wood construction.

As such, research is being conducted on sound insulation and fire resistance performance of wooden apartment housing tested (or constructed?) between 2018 to 2021. The Korea Institute of Civil Engineering and Building Technology, an accrediting organization for fire resistance, is conducting the research jointly with the National Institute of Forest Science — an organization affiliated with the Korea Forest Service.

On November 26, 2020, a Notice was issued by the Korea Institute of Civil Engineering and Building Technology on Fire Resistance Construction Standard Certification for Structural Glue-Laminated Timber. Structural Glue-Laminated Timber products, produced by the KS-certified domestic manufacturers, can be certified as fire-resistant up to 2 hours — without fire resistance performance testing. This will save a lot of time and money.

In the future, we plan to expand the scope of fire-resistant certification to other structural wood products such as Cross-Laminated Timber (CLT).

Current Korean multi-family housing cannot use wooden floors. This is because the 2015 Housing Act mandated the use of 210 mm thick concrete floors as the standard to be applied as floor structures for apartment housing, in order to reduce noise between floors. In order to meet the current sound reduction requirements for wood-structure apartments, wooden floors have to be much thicker — thus impacting economics.

In order to optimize floor construction via improved materials and structural changes, part of KFS’s mandate is to conduct sound-insulation performance tests on wooden construction.

To expand on that, we are building a mock-up CLT multi-family building for the purpose of sound testing. Heavy rubber balls replace the conventional tire machine, which better simulates the characteristics of children jumping and running at home. We expect to be able to issue acoustic certifications from construction drawing approval to post-construction in-situ testing.

The Korea Forest Service is also supporting the development of new technologies through the New Technology Certification system for wood products. This year, we are investing KRW 4.8 billion into 23 government-sponsored research projects. Development of these new products and technologies will add more value to the wood building industry, and we intend to gradually expand the scope of research activities.

Please tell us about your vision for the realization of large-scale wooden construction, and what it means to the general public and wood building industry.

The Korean timber industry is struggling in a long-term construction recession. In particular, the domestic forest industry is facing challenges due to misconceptions around logging being damaging to the environment.

In order to build a carbon-neutral society and fulfill the Korean government’s Green New Deal of July 2020, the current construction methodologies must be reimagined.

Our society has no choice but to think deeply about the efficient reduction and storage of carbon through the use of wood. This will be a new opportunity for the wood building industry.

As aKorean, I urge everyone to consider what will help our country and the global environment.

There are many benefits of building with wood. To name just a few: wood does not emit radon, and wood contains various active organic compounds that are good for health. In the case of fire, a wood structure is not subject to sudden structural collapse when it passes a critical temperature — unlike steel.

While it may not be realistic to bring the natural benefits of wood into your home by living directly in the forest, building with wood is a wonderful and environmentally friendly way to bring more nature into your life.

Finally, please introduce the Timber Industry Division of the Korea Forest Service.

The Timber Industry Division oversees the following five branches: timber industry policy, forest bioenergy, timber quality control, timber distribution and use and forest roads.

In the field of wood industry policy, we support builders, manufacturers, and designers; as well as operating certification schemes including the certification of new technology.

In the field of forest bioenergy, we support the use of biomass as a source of energy in wood pellet boilers, the creation of energy-independent forest villages, and improved utilization of forest biomass.

The timber quality section maintains standards for wood products and ensures consumer safety by operating a third-party certification system for wood products.

In the area of timber distribution and use, we provide wood education to support the revitalization of Korea’s wood culture and manage the distribution and use of domestic wood resources wood.

The forest road unit maintains and expands the forest road network, the logistical basis of wood supply and forest management. We also keep forest roads accessible in preparation to fight forest fires.