Removing Barriers for NLT Use in Japan

COFI has been working with the Japan 2×4 Home Builder’s Association to facilitate the spread of large-scale wooden buildings using Nail-Laminated Timber (NLT) in horizontal diaphragms such as roof and floor structures. This is part of our Canada Wood Market Access technical projects for Fiscal 2019-2020. One of the goals for this fiscal year was to obtain ministerial approvals for 1-hour quasi fire resistive floor structure and 30-minute quasi-fire resistive structure. Another objective of the project was to seek a voluntary evaluation from an MLIT1)-designated third party performance evaluation body.

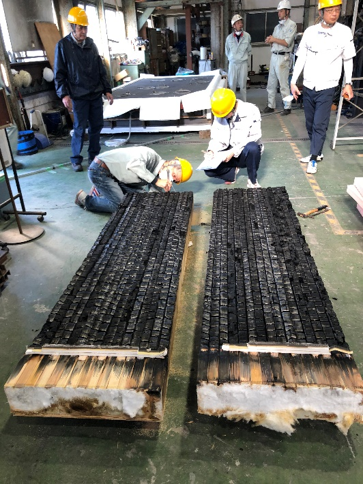

Both the 1-hour and the 30-minute quasi fire testing were successfully completed at the laboratories of Centre for Better Living (floor) and Japan Testing Centre for Construction Materials (roof). We are at the final stage of obtaining the approvals as we have submitted the approval application to MLIT after the series of the evaluation committee judgements. With the 2019 revision to the Building Standard Law and the MLIT approvals for quasi fire resistive approvals, visually exposed NLT will be able to be structural elements in the large-scale buildings that requires fire resistive performance.

As for the structural performance, NLT with butt joints requires a solution to verify how inferior such NLTs are to the NLTs without butt joints. NLT with butt joints comprise of dimension lumber pieces lined up sequentially lengthwise to achieve large spans. COFI and the Japan 2×4 Home Builder’s Association jointly worked for obtaining a structural evaluation certificate from HOWTEC2), one of the MLIT-designated performance evaluation bodies. Under the guidance from the evaluation committee members, we conducted bending tests with butt-joints at the Gunma Prefectural Forestry Laboratory from September through December 2019. These were the 4-point loading bending test to 2×12 and 2×8 Canadian SPF. After collecting the data, we confirmed if our numerical modelling works accurately on the rotational rigidity at the butt joint.

In addition to the bending test mentioned above, we also conducted the creep test to the NLT specimens to confirm the bending deformation over a long duration of time (1 month). The creep test set-up has been located at the FRMO (Forest Research and Management Organization) laboratory in Tsukuba City. All NLT test work is expected to be completed by the end of this fiscal year.